Wastewater treatment is a necessary endeavor. Understanding the needs of its customers, Smith & Loveless continually looks at of delivering ways of delivering efficient wastewater treatment and water reuse at a lower cost. Let’s take a closer look at how this is achieved with S&L’s pre-engineered OXIGEST® treatment system approaches.

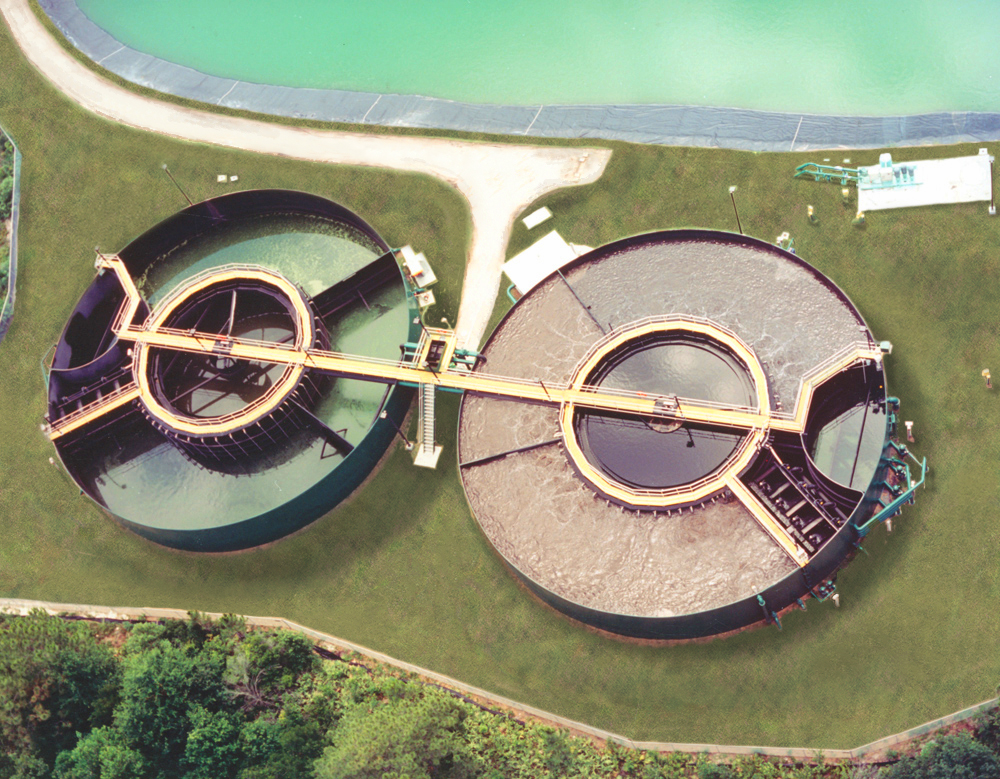

Conventional concrete built-in-place wastewater treatment plants typically comprise centralized plants that serve cities and district communities, receiving flows from all or part of its designated regions. Meanwhile, Smith & Loveless OXIGEST® systems offer a tailored solution for smaller-scale applications with flows between 0.1 and 3.0 MGD (380 to 11,499 cmd) through a single unit. Also known as decentralized wastewater treatment systems, these plans can treat and manage wastewater at or near its point of origin, and depending on permit requirements allow for reuse, discharge to a city sewer, or return to the environment.

Regardless of type, all wastewater treatment plants must align with standards originally set in motion by the Clean Water Act enacted in 1972. It mandates the removal of harmful pollutants from wastewater effluent before its return to natural bodies of water. This regulatory framework helps ensure the protection of public health and the environment by regulating various types of contaminants. The common effluent parameters that are often regulated are:

Total Suspended Solids (TSS)

Regulation: Effluent standards often include limits on the concentration of total suspended solids. This parameter indicates the number of solid particles that remain in the water after treatment.

Importance: Excessive suspended solids can lead to water cloudiness and may contain harmful pollutants, impacting aquatic ecosystems.

Biochemical Oxygen Demand (BOD):

Regulation: BOD measures the amount of oxygen consumed by microorganisms as they decompose organic matter in the water. Regulatory standards often set limits on BOD levels.

Importance: Elevated BOD levels in effluent can deplete oxygen in receiving water bodies, potentially harming aquatic life.

Chemical Oxygen Demand (COD):

Regulation: COD is a measure of the oxygen required to chemically oxidize both organic and inorganic matter in the water. Some regulatory frameworks may include COD limits.

Importance: High COD levels can indicate the presence of pollutants that may be harmful to the environment.

Nutrients (Nitrogen and Phosphorus):

Regulation: Effluent requirements may include limits on nitrogen and phosphorus levels, as these nutrients can contribute to eutrophication in receiving waters.

Importance: Excessive nutrients can lead to the overgrowth of algae and aquatic plants, disrupting the balance of ecosystems.

Pathogen Reduction:

Regulation: Effluent standards often include requirements for the reduction of pathogens, such as bacteria and viruses, to protect public health.

Importance: Effective pathogen reduction is critical to prevent the spread of waterborne diseases.

pH (Acidity or Alkalinity):

Regulation: Standards may specify acceptable pH levels in effluent. pH measures the acidity or alkalinity of the water.

Importance: Extreme pH levels can impact the aquatic environment and the ability of organisms to thrive.

Toxic Substances:

Regulation: Limits may be set for specific toxic substances, depending on the industrial or residential sources of wastewater.

Importance: Preventing the release of toxic substances is crucial to protect both aquatic ecosystems and human health.

As we can see, many considerations go into protecting the quality of water throughout the wastewater treatment process. The strength of the waste stream and the desired effluent quality dictates the process selections. The more advanced the treatment or higher the effluent quality usually demands a higher cost.

However, the operation of such processes is not the only cost when building a wastewater treatment system. While the project requirements vary based on factors such as the scale of the system, local regulations, and the type of wastewater being treated, the fundamental elements involved in the construction of such a system can also easily drive up capital and operational costs. This is where the Smith & Loveless OXIGEST® field-erected treatment system comes into play.

Smith & Loveless took into consideration many of the costs when developing the OXIGEST® system, as well as every way possible to provide the most advanced treatment at this scale. S&L aimed to create a treatment system that achieves and exceeds industry standards set for wastewater effluent, but at a price that would allow for wide-spread adoption by small municipalities, private developments, military installations, and even industrial systems like oil and gas refineries, chemical and petrochemical facilities, food and beverage, breweries, and wineries.

OXIGEST® wastewater treatment systems achieve this by offering flexible treatment for a variety of process options. Each system is custom-built for the specific project requirements and can incorporate a wide variety of process variations. Whether a system needs a specific process zone addition like grit removal, flow equalization, bio-nutrient removal (BNR), filtration, disinfection, sludge holding, membrane bioreactors (MBR), or other customized zones, they can all be added.

This level of flexibility allows the Model R OXIGEST® wastewater treatment system to achieve effluent qualities of:

And when incorporating S&L membranes, the OXIGEST® MBR™ wastewater treatment system will achieve effluent qualities of:

Smith & Loveless didn’t just stop at tackling the water quality side of the equation, they wanted to bring the life cycle costs of building and operating these systems down too. Field-erected OXIGEST® steel treatment plants require significantly less capital and operational costs than fully concrete built-in-place plants of the same capacity.

Up front, S&L plants install more quickly and cost-effectively through quality-controlled manufacturing and time-efficient on-site assembly. Because OXIGEST® designs offer smaller total footprints and significant reduction of yard piping and conduit (and associated long-term maintenance), life cycle costs (capital + O&M) are typically less than half compared to conventional concrete plants.

These systems come with factory finished carbon steel or optional stainless-steel tankage and components. Hybrid steel-concrete arrangements are also possible.

By achieving industry standards for water reuse while offering smaller up-front capital investment, quicker installation, lower operational costs, -- all of which reduces total life cycle costs –, Smith & Loveless is proud to stand by the proven field erected OXIGEST® wastewater treatment system.

If you would like to learn more about the advantages of the Model R OXIGEST® (#4100) or OXIGEST® MBR™ (#4144), and the benefits they can offer for your wastewater treatment needs, you can find brochures for each of these here:

Or, if you would like to inquire if either of these are right for your project, reach out to S&L here:

800-898-9122 or Answers@SmithAndLoveless.com